All Products

Contact Person :

Sara

Phone Number :

+86-18117348869

WhatsApp :

+8618117348869

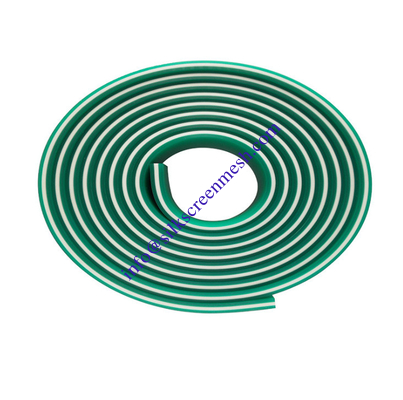

Flat Scratch Resistant Solvent Ink Scraper Screen Printing Squeegee Strip

| Place of Origin | CHINA |

|---|---|

| Brand Name | SPRING |

| Certification | ISO9001 |

| Minimum Order Quantity | 2roll |

| Price | www.silkscreenmesh.com |

| Packaging Details | 1. in roll with plastic 2.in wooden case or carton 3.as your requirement |

| Delivery Time | 3-7 Days |

| Payment Terms | TT/LC/Western Union/paypal/others |

| Supply Ability | 5000000m/month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Processing | Customization | Type | Squeegee |

|---|---|---|---|

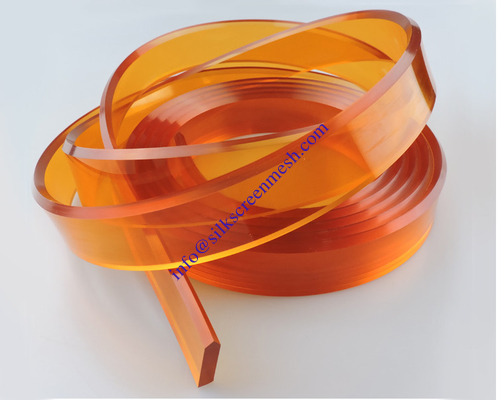

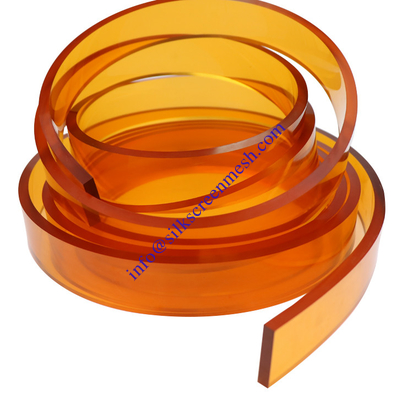

| Specifications | 50*9*3660mm 75 Degrees | Knife Shape | Sharp / Flat / Oblique |

| Color | Green / Red / Blue / Brown Color Can Be Ordered |

Product Description

1. Product introduction

Squeegee is a strip used in the screen printing process and generally becomes a squeegee. Most of them are made of PU materials. Depending on the characteristics of the screen printing substrate, the accuracy of the printed pattern, and the printing method, it is possible to select the squeegee of different hardness and cross-sectional shape.

2. Selection of hardness and cross-sectional shape of the scraping rubber

Hardness selection

45°---65° (soft squeegee, suitable for printing uneven surface products)

65°---80° (comprehensive performance, suitable for all kinds of printed matter)

75°---95° (wear resistance, good solvent resistance, suitable for printing fine patterns)

Section shape selection

Flat mouth scraping glue: common shape, with a certain adaptability, can withstand the highest pressure.

Sharp squeegee: It has good flexibility, compliance, and reduced pressure. It is suitable for printing on irregular surfaces and irregular shape substrates.

3. How to use

When using, try to avoid excessive pressure on the stencil. This will cause the ink layer to be extremely thick, difficult to control, and excessively wear the stencil. Therefore, the correct way is to have both ends of the squeegee and the edge of the screen. Proper distance, then print with appropriate pressure. Do not apply pressure when the squeegee is placed in the handle or use too thick a size to force it in. The squeegee should be allowed to rest regularly instead of continuously.

4. Cleaning

Wipe off excess ink with a cloth and then wash it with a soft cloth dampened with a suitable solvent. Do not use strong solvents, especially ink thinners, to clean the squeegee. The gel should be left idle after grinding or before use to completely evaporate the solution.

5. Grinding

It can be ground in a general and general way: belt type, roller type, knife cutting type can only grind dry squeegee, and it can't be wiped with solvent immediately after grinding.

6. Storage

For long-term storage, the squeegee should be wrapped and placed in a dry and cool room to avoid direct light exposure. Otherwise, the performance and hardness of the squeegee will change.

Recommended Products