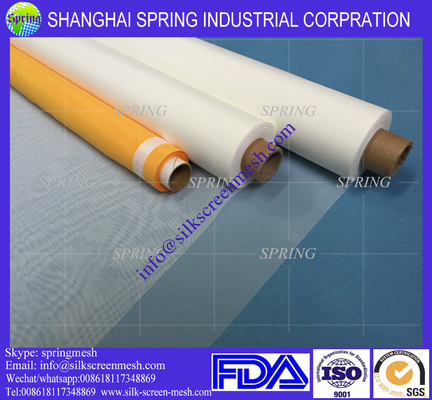

textile printing/net fabric

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x100% Polyester Monofilament Mesh/textile printing/net fabric

Polyester has replaced traditional silk as the fabric of choice among screen printers all over the world because of its tensile strength, elastic memory and resistance to chemicals, abrasion heat and moisture. Polyester is woven from yarn that is extruded from heated polyester into a single strand. The extruded thread is the spun to a precise diameter.

textile printing/net fabric Features:

-

Made of 100% polyester with higher tension threshold and breaking point

-

Resist to chemicals, abrasion, heat and moisture

-

Less tension loss during the stretching process

-

Improved registration due to stable fabric tension

-

Low Elongation

-

Excellent Tear Resistance

-

Very Good Dimensional Stability

-

Faster tensioning without damage to the threads

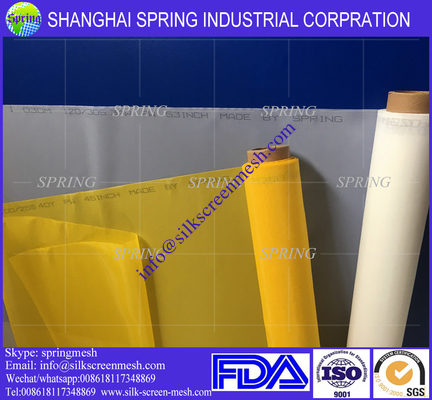

Screen mesh means mesh number of per inch. English unit of screen thread is T (Thread).

Thread general means the density of silk. The higher the thread, the silk is more closely and the opening is smaller, conversely, the lower the thread, the silk is sparser, and the opening is larger, such as the 150 Threads, it means there are 150 net wires in per CM. The smaller the mesh, the worse ink can through it. The larger the mesh, the better ink can through it.

You should choose screen of different thread when using different ink and pigment, according to your actual accurate need. Recommendation: 80 to 120 mesh: have mostly been used for T-shirt printing (water based ink). 160to 180mesh: have mostly been used for plastic, metal, glass and other high resolution printing product. (solvent ink)

Tips about screen to improve screen printing quality

The rule of thumb with screens and meshes is that the tighter they are, the better the quality of output. The benefits of a tight mesh include a decreased likelihood of the mesh moving out of registration during printing and lesser chances of one color bleeding into another.

Tight screens have lower resistance when pulling the squeegee thereby reducing labor and cutting the ink cleanly.

A tight mesh also deposits the ink evenly onto the substrate. A soft mesh may have deposits of ink towards the edges thus printing with more ink in the center and less towards the corners. The uneven deposit of ink results in lowered printing quality.

![]()

![]()