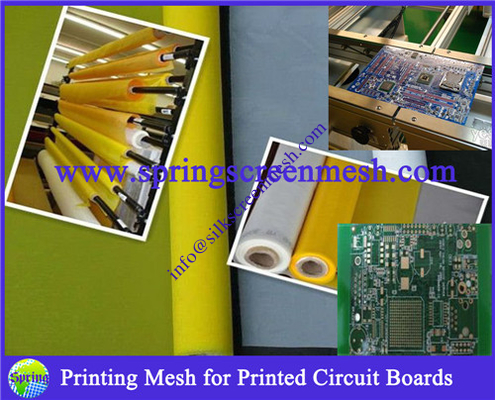

PCB printing material 100% polyester screen mesh

| Place of Origin | Shanghai China |

|---|---|

| Brand Name | SPRING |

| Certification | ISO9001 |

| Model Number | DPP |

| Minimum Order Quantity | 30m |

| Price | 1-50$/m |

| Packaging Details | Paper tube, plastic bag, carton box, sailcloth or according to the customer's special requests |

| Delivery Time | 3-5 Days |

| Payment Terms | L/C, T/T, Western Union, Paypal |

| Supply Ability | 50000000m/month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Mesh Count | 77mesh/cm | Material | 100% Polyester |

|---|---|---|---|

| Weave Type | Plain | Elasticity | Low |

| Printing | Silk Screen Printing | Monofilament Style | Yes |

PCB printing material 100% polyester screen mesh

Specifications

Warp/weft elongation:average and low

Much high tensile strength

Perfect network version of the adhesion

printing mesh of printed circuit board PCB /PCB printed screen printing mesh

Artwork

Printed circuit board artwork will either be fine lines and intricate graphic features (pattern printing), floods with small squares or circles (solder mask printing) or fine text (legend printing). Because of the required pattern, solder mask and legend artwork is typically similar from one PCB application to another.

For optimum image results, it is recommended to stretch the mesh at an angle from 15 to 30 degrees (mesh is stretched in the clamps at 90 degrees, and the frames are angled under the mesh). Mesh is typically tensioned to 28 to 30 N/cm (0.970-0.910 mm), and should relax for 48-hours before exposure.

Screens are usually coated with solvent resistant emulsions that have a solids content of 30% or greater. For optimum image results, the target EOM for PCB screens is 10% – 30% of the mesh thickness. The Rz of the stencil should be less than 5 microns. Artwork is exposed by conventional exposure techniques, using films that are 0.18 mm thick and have a resolution of at least 6000 dpi.

It is common that screens used for PCB printing are reclaimed and used again; however, screens that have been reclaimed are used on jobs that are not critical.

Mesh Select

DPP120T/300-35,

DPP100T-40,DPP90T-48,

DPP77T-55,DPP61T-64,

DPP59T-55,DPP54T-64,

DPP47T-64,DPP43T-80,

DPP40T-80,DPP32-80,

DPP36T-90

Contact Us:

Sales Maganer: Sara

E-mail: info@silkscreenmesh.com

Skype: springmesh

MSN: springmesh@live.com

Yahoo: springmesh@yahoo.com

Gmail: springscreenmesh@gmail.com

Website: www.springscreenmesh.com

Mob: 86-13166408569/18117348869