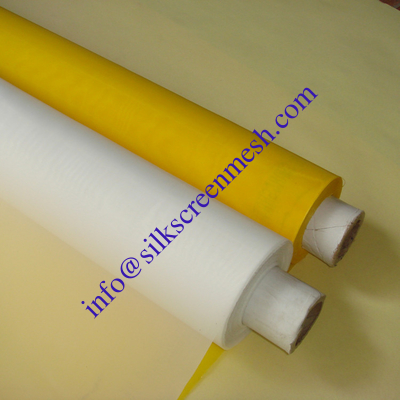

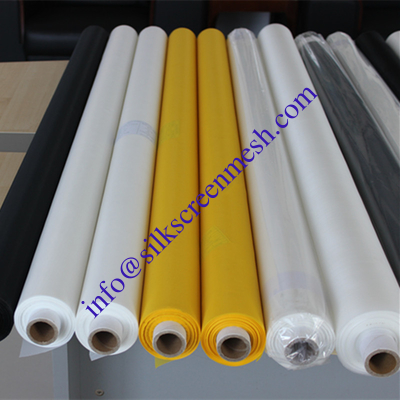

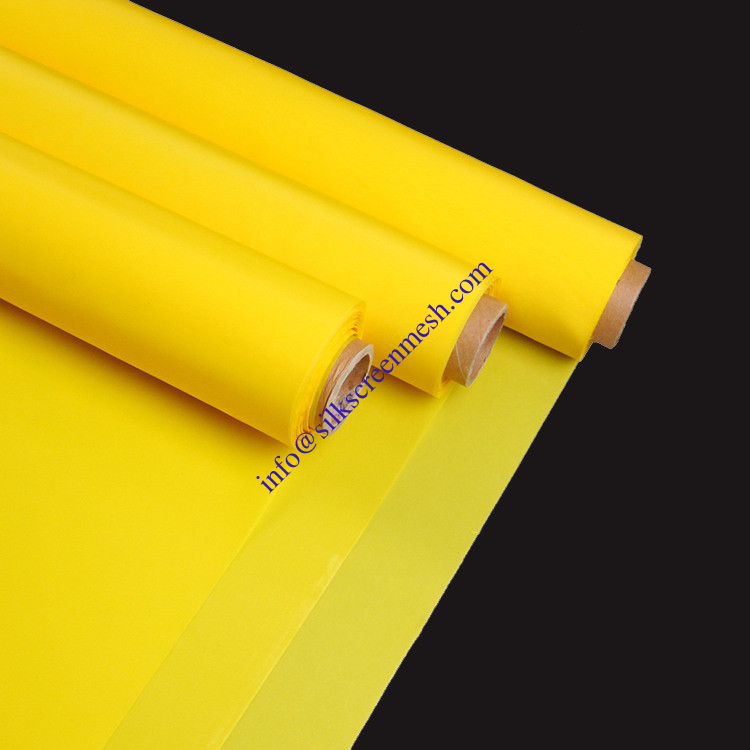

product description

High-tension polyester mesh is a high-precision, high-quality wire mesh suitable for use in various screen printing processes. It has high tension, good ink permeability, high image resolution and good scratch resistance.

1. Opening control: using ultra-high precision imported steel boring to control the consistency of radial opening of the screen; using microcomputer program to control the consistency of the latitudinal opening of the screen;

2. Ink permeability: After submicron trimming of the screen surface, the contact area of the adhesive/ink particles can be reduced, and the efficiency of the adhesive/ink penetration through the screen can be improved, and the printing resolution can be optimized to become halftone and fine. Ideal for line printing. The low surface dyne value allows the ink to easily penetrate the mesh and separate from the screen while increasing the dot performance of the screen.

3. Scratch resistance: It is produced by using special sheath core structure imported raw materials. The surface soft polyester component reduces screen scratching wear and prolongs the use time.

4. Physical properties: The tensile strength of the wire mesh is twice as high as that of the stainless steel wire mesh. The TAC technology is used to control the uniform force of each raw material, thereby increasing the maximum tension of the wire mesh product. It can be stretched to a high screen tension when necessary, minimizing the printing pitch and reducing the blade press pressure to ensure dimensional accuracy.

5. Smooth surface: Microfiber filaments and a smooth mesh surface help to achieve a suitable emulsion Rz value, which is a key factor in achieving the highest resolution.

6. Exposure latitude: The screen has not only improved the adhesion of the emulsion/capillary film; it also extends the exposure tolerance limit (underexposure), especially for detail-oriented applications.

Application field

Wire mesh products are widely used in electronic circuit boards, mobile phone lenses, membrane switches, advertising signs, glass decals, packaging, metal plastics, flower fat and some high-demand dot printing, printing, ceramic printing and other industries to meet the different needs of customers. It is your best choice.

| 100% Polyester Monofilament Mesh |

| Type |

Weave |

Mesh/CM |

Mesh/inch |

Wire Dia.

(um) |

Mesh Opening(um) |

Open Area

(%) |

Thickness

(um) |

| PET-7/1080 |

PW |

7 |

18 |

350 |

1080 |

57 |

640 |

| PET-8/950 |

PW |

8 |

20 |

300 |

950 |

58 |

550 |

| PET-10/800 |

PW |

10 |

25 |

200 |

800 |

64 |

380 |

| PET-10/750 |

PW |

10 |

25 |

250 |

750 |

56 |

480 |

| PET-12/633 |

PW |

12 |

30 |

200 |

633 |

58 |

390 |

| PET-12/583 |

PW |

12 |

30 |

250 |

583 |

49 |

480 |

| PET-16/425 |

PW |

16 |

40 |

200 |

425 |

46 |

400 |

| PET-20/420 |

PW |

20 |

50 |

80 |

420 |

71 |

140 |

| PET-20/400 |

PW |

20 |

50 |

100 |

400 |

64 |

185 |

| PET-20/380 |

PW |

20 |

50 |

120 |

380 |

58 |

230 |

| PET-20/350 |

PW |

20 |

50 |

150 |

350 |

49 |

290 |

| PET-24/337 |

PW |

24 |

60 |

80 |

337 |

65 |

150 |

| PET-24/317 |

PW |

24 |

60 |

100 |

317 |

58 |

190 |

| PET-24/297 |

PW |

24 |

60 |

120 |

297 |

51 |

235 |

| PET-24/267 |

PW |

24 |

60 |

150 |

267 |

41 |

295 |

| PET-29/225 |

PW |

29 |

74 |

120 |

225 |

43 |

238 |

| PET-32/249 |

PW |

32 |

80 |

64 |

249 |

63 |

115 |

| PET-32/233 |

PW |

32 |

80 |

80 |

233 |

55 |

150 |

| PET-32/213 |

PW |

32 |

80 |

100 |

213 |

46 |

180 |

| PET-34/194 |

PW |

34 |

86 |

100 |

194 |

44 |

185 |

| PET-36/178 |

PW |

36 |

90 |

100 |

178 |

41 |

190 |

| PET-39/201 |

PW |

39 |

99 |

55 |

201 |

62 |

90 |

| PET-39/176 |

PW |

39 |

99 |

80 |

176 |

47 |

150 |

| PET-39/156 |

PW |

39 |

99 |

100 |

156 |

37 |

195 |

| PET-43/153 |

PW |

43 |

110 |

80 |

153 |

43 |

155 |

| PET-47/158 |

PW |

47 |

120 |

55 |

158 |

55 |

95 |

| PET-47/142 |

PW |

47 |

120 |

71 |

142 |

44 |

130 |

| PET-53/134 |

PW |

53 |

135 |

55 |

134 |

50 |

98 |

| PET-53/125 |

PW |

53 |

135 |

64 |

125 |

44 |

115 |

| PET-53/118 |

PW |

53 |

135 |

71 |

118 |

39 |

133 |

| PET-59/114 |

PW |

59 |

150 |

55 |

114 |

46 |

100 |

| PET-59/105 |

PW |

59 |

150 |

64 |

105 |

39 |

118 |

| PET-64/101 |

PW |

64 |

163 |

55 |

101 |

42 |

102 |

| PET-64/92 |

PW |

64 |

163 |

64 |

92 |

35 |

120 |

| PET-72/91 |

PW |

72 |

183 |

48 |

91 |

43 |

75 |

| PET-72/84 |

PW |

72 |

183 |

55 |

84 |

37 |

105 |

| PET-77/75 |

PW |

77 |

195 |

55 |

75 |

33 |

108 |

| PET-80/77 |

PW |

80 |

203 |

48 |

77 |

38 |

77 |

| PET-90/63 |

PW |

90 |

230 |

48 |

63 |

32 |

80 |

| PET-100/60 |

PW |

100 |

254 |

40 |

60 |

36 |

65 |

| PET-110/51 |

PW |

110 |

280 |

40 |

51 |

31 |

70 |

| PET-120/48 |

PW |

120 |

305 |

34 |

48 |

35 |

63 |

| PET-120/43 |

PW |

120 |

305 |

40 |

43 |

27 |

75 |

| PET-140/37 |

PW |

140 |

355 |

34 |

37 |

27 |

65 |

| PET-140/36 |

PW |

150 |

380 |

31 |

36 |

29 |

52 |

| PET-150/33 |

PW |

150 |

380 |

34 |

33 |

24 |

56 |

| PET-165/34 |

PW |

165 |

420 |

27 |

34 |

31 |

50 |

| PET-165/30 |

PW |

165 |

420 |

31 |

30 |

24 |

58 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!